PE Process Engineering package

PE Process Engineering expansionThis expansion provides simulation of special heat transfer conditions both on the hot and cold side.

It is based on a formula interface intended to add easily calculation formulas for heat transfer coeffi-cients. The calculation is bases on an individual set of parameters for each of the formulas. In this way the software can be customized to new requirements without changes in the core parts of the calculation algorithms. All formulas can be used in steady state and in transient simulation.

In SIMU-THERM 6.5 the following heat transfer calculation are available:

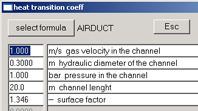

AIRDUCT – convective heat transfer in air channel

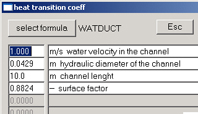

WATDUCT – convective heat transfer in water channel

WATFILM – convective heat transfer under a falling water film

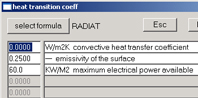

RADIAT – thermal radiation plus a fixed convective component

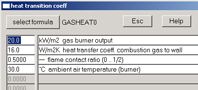

GASHEAT0 – heating with limited burner capacity, flame temperature known

GASHEAT – heating with limited burner capacity, gas exit temperature known

GASCOOL – cooling with a small air flow on the hot face

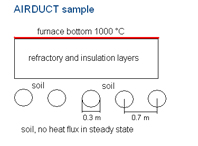

AIRDUCT application sample

|  |

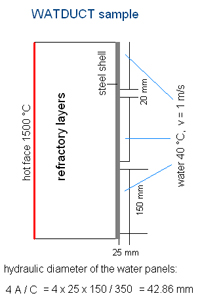

WATDUCT application sample

|  |

In the panels water of 50 °C is flowing with velocity

1 m/s. The length of the water flow is 10 m.

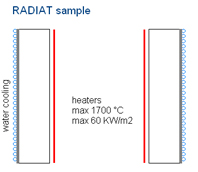

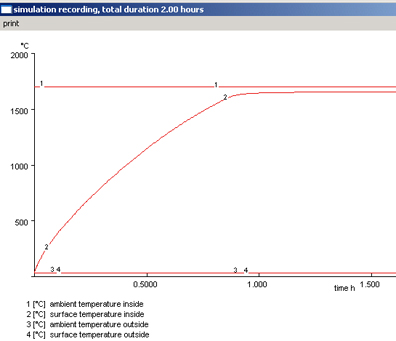

RADIAT application sample

|  |

Simulation result: the maximum inside temperature is reached after about 1 hour.

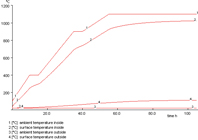

GASHEAT application sample

|  |

Heating up a furnace is performed with 20 kW gas burner capacity per square meter wall.

Due to the limitation of the burner capacity, there is a large difference between the flame tempera-ture and the surface temperature. Note that the curve of the inside surface temperature has become very smooth.